2024 Impact Report

Everyone deserves a well designed place they are proud to call home.

At Module, we’re on a mission to make high-quality, human-centered housing attainable through the power of offsite construction.

INTRO

Long before ESG became a buzzword, we’ve been living its principles. Sustainability, equity, and purpose are baked into the way we design homes, build partnerships, and create opportunities for communities to thrive. Last year, we took bold steps to bring our vision to life—opening our own manufacturing facility in Pittsburgh, PA, creating opportunities through workforce development, empowering developers to build with purpose, and of course, delivering thoughtfully designed, sustainable homes.

Our 2024 Impact Report shares the faces, facts, and stories behind our work. Explore how we’re reshaping the future of housing through innovation, grit, and a commitment to doing better.

Highlights include:

-

Mission-Driven Developer Program

-

Last Mile Facility

-

5 Energy Star Certified Homes

Mission-Driven Developer Program

Module's Mission-Driven Developer Program (MDDP) supports housing providers developing new affordable, mixed-income, and workforce housing in historically disinvested communities.

We received over 40 applicants from 15 states across the U.S.

In 2024, we’ve had the privilege to work with 8 developers across 5 states—including 7 women or developers of color.

Module has offered discounted design services and technical assistance to this cohort. Developers in the program will/have received priority on Module’s manufacturing line, significantly reducing cycle times for projects that deliver affordable housing where they are needed most.

As part of the MDDP program, we’ve trained 36 developers on how to integrate offsite, sustainable building practices into their projects.

From factory tours to speaking events, we’ve connected with hundreds of people this year, sparking conversations and building momentum for change.

ENVIRONMENTAL IMPACT

Building homes shouldn’t come at the cost of the planet. Our homes have less waste and more impact, including:

Up to 20% lower lifecycle cost, streamlined production system, and design-build process ensuring quality control.

Repeatable, human-centered designs that are 70% more energy efficient than existing homes.

-

Our homes have a cutting-edge Unico system that uses small, efficient ducts to keep the air flowing and comfortable throughout your home. This means lower energy bills and a healthier, more comfortable living space for you.

-

An energy recovery ventilator (ERV) acts as the lungs of the home. By transferring heat energy between incoming and outgoing airstreams, the ERV not only maintains a fresh and healthy indoor environment but also optimizes HVAC efficiency, leading to lower energy costs and a reduced carbon footprint.

-

This home features super efficient all-electric components. Ductless heating and cooling, a hybrid water heater that can reduce usage up to 70% & EnergyStar Appliances and WaterSense Fixtures that help save on utilities & reduce environmental impact.

View modular construction in action with our #ConstructionUpdates on insta leading up to set day on Ledlie Street.

Energy Star Homes

5 of our homes received Energy Star Certification in 2024.

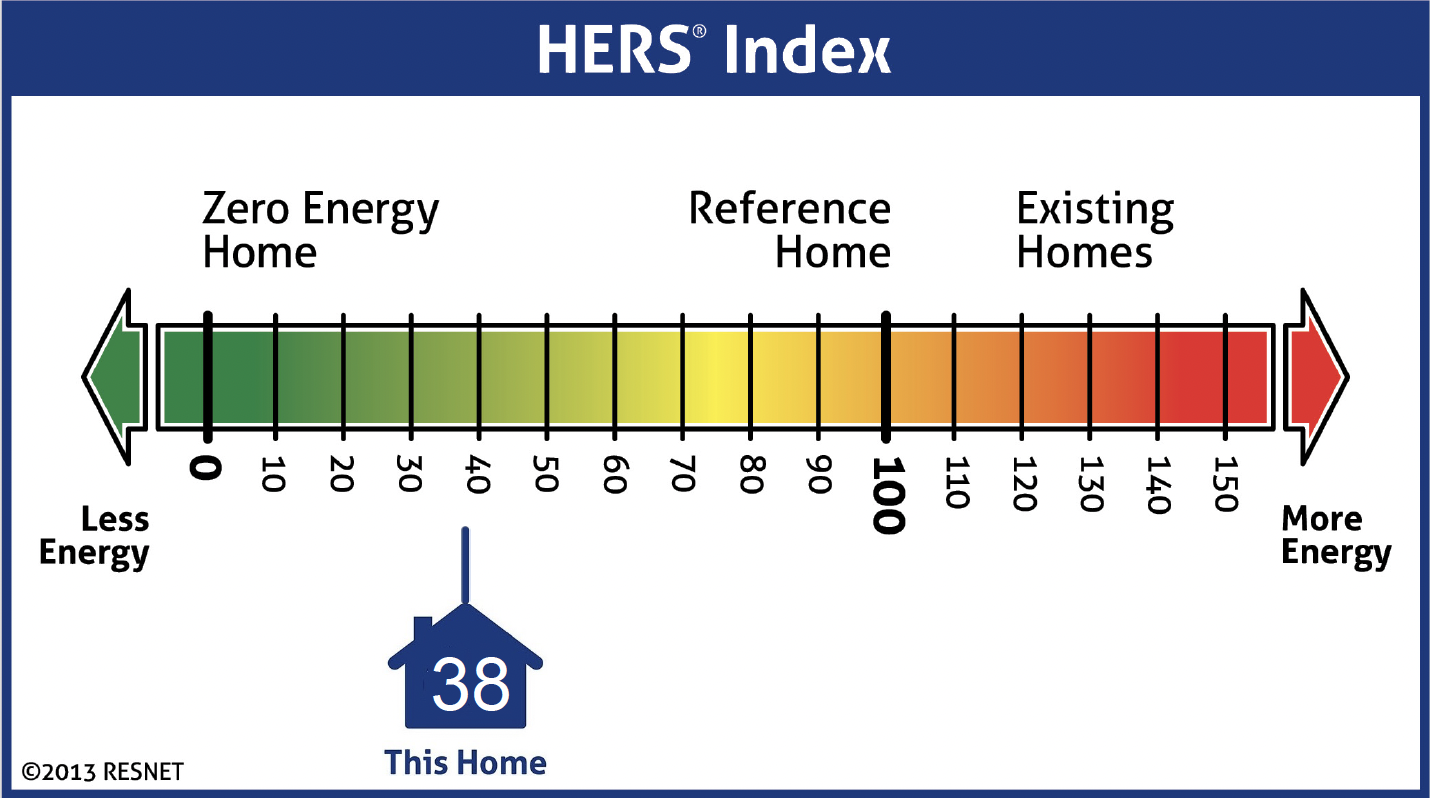

What does a HERS Index Rating between 38-50 mean?

50-70% more efficient than a standard new home

Estimated annual energy savings ranging from $890-$1250

GOVERNANCE

At Module, we are dedicated to partnering with Minority and Women-Owned Enterprises.

Module Design, Build, and Manufacturing collaborates with the Trade Institute of Pittsburgh in a variety of ways empowering more women and minorities to enter the construction trades.

At Module Build, our construction arm, we work with several Minority and Women-owned subcontractor businesses to finish the homes on-site with local tradespeople.

Module team members are active members of their communities and serve on the board of Partners4Work, and BLUE Missions.

In 2024, we continued our work with the Last Mile Network, an urban manufacturing model that has created jobs in our hometown and that we’re bringing to other geographies.

Part of this program includes offering educational resources to Design and Construction partners. With the support of Fannie Mae, Module is scaling the Last Mile concept beyond Pittsburgh.

Our Construction Partners program is designed for general contractors who believe there are better ways to build. Module construction partners learn how to install modular boxes and the difference between traditional stick-built and off-site construction.

Design Partners Through an online training course, architects learn about the Module brand and the difference between traditional and modular construction. By bringing on Module Design Partners in other parts of the country, we can help architect-partners diversify their customer base, and put more Module homes in the hands of families looking for a sustainable solution for new construction.

Our story continues…

Our work was featured in publications like Forbes and highlighted at industry-leading events such as Blueprint, the MHBA Conference, Homes within Reach Conference, and AIA webinars.

05.10.24 | Forbes | Offsite Housing Construction for Economy and for Humanity

09.17.24 | Virginia Housing | 5 Innovation Grant Winners Are Set to Take Housing to New Heights

10.24.24 | Enterprise Community Partners, Wells Fargo Foundation, Ivory Innovations, Terner Labs | The Case for Innovation in Housing: How Local Governments Can Drive Solutions

10.23.24 | WESA | A new factory produces homes in Pittsburgh, expanding the region's housing supply

10.31.24 | URA | URA Joins Amani Christian CDC to Celebrate New Affordable Modular Housing in the Hill District

What’s Next? As we look to 2025 and beyond, we’re doubling down on our mission:

Expand the Last Mile Network to bring sustainable housing to more states.

Certify the Last Mile Facility in additional regions, including Virginia, Maryland, and Ohio.

Grow our workforce development initiatives, to empower more individuals.

Deliver more homes and continue reducing the environmental impact of construction.

With every step forward, we’re proving that bold ideas and hard work can drive meaningful change. But we’re not doing it alone. Every home we build, every person we train, and every story we share is possible because of the partnerships, communities, and people who support and believe in what we’re doing.

Here’s to building a better future together.

SOCIAL IMPACT

The Last Mile Facility, our 22,000 square foot manufacturing hub located in Pittsburgh, PA was intentionally opened with a low barrier to entry. It has become a beacon for workforce development and community education.

We’re proud partners with the Trade Institute of Pittsburgh (TIP). We work with TIP in a variety of ways to enhance workforce development training both at the factory and on the job site.

2 carpentry apprentices hired. 12 individuals trained on the job or at the factory.